Feeding granularity: 50-600 meshes

Handling capacity: 1-10T

Weight:Different models, different materials, different prices.

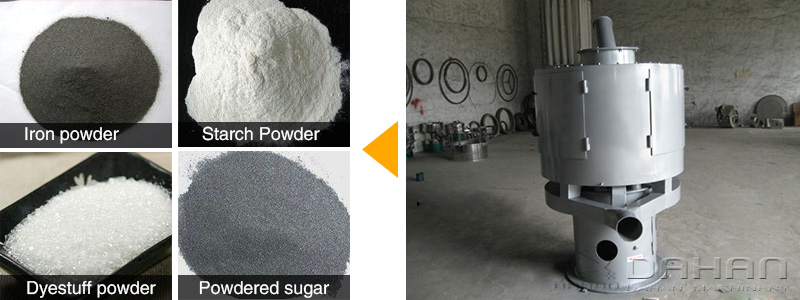

Application field:The fine powder that is difficult to screen.

Applicable material:Alumina powder, graphite powder, sulphur powder, light calcium powder, active calcium powder, activated carbon powder, epoxy resin powder, magnesium oxide, starch, traditional Chinese medicine powder, fly ash, zinc powder, quartz sand powder, gold powder, ceramics powder, hawthorn powder, fruit powder, calcium hydroxide powder, pesticide powder, konjaku flour, phosphor powder, wood powder, flour, manganese dioxide, bakelite powder,pearl rock powder ,iron powder, cotton velvet, etc.