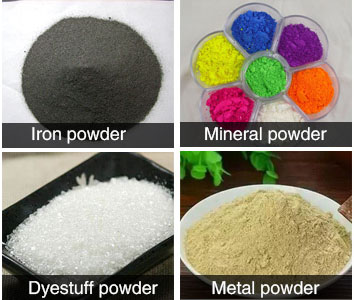

Product overview :

Gas protected vibrating screen is a new type of screening equipment developed by Dahan machinery, which is made of 304 stainless steel material, gas protection hose, anti-static device and so on. It has been continuously tested by Dahan mechanical engineers. Gas protected vibrating screen model is from the diameter of 400-1800mm. The price of gas protected vibrating screen varies according to material, diameter and number of layers. Any particle, powder and mucus can be screened in a certain range. Screening fineness is 500 meshes or 0.028 mm, and filtration size can be as small as 5 microns. Grading screening, can screen one to five layers of screen, can simultaneously carry out two to six levels of separation or filtering.

Product features :

1. High efficiency, delicate and durable design, any powder, mucus can be screened.

2. It is easy to change the net, easy to operate and easy to clean.

3. Mesh is not blocked, powder is not flying, can be screened to 500 meshes or 0.028mm.

4. Impurities, coarse materials automatically discharged, can be continuous operation.

5. Unique network frame design, long screen use time, fast network change, only 3-5 minutes.

6. Small size, space saving, easy to move.

7. Screen machine can be stacked up to five layers, three layers are recommended.