Product overview:

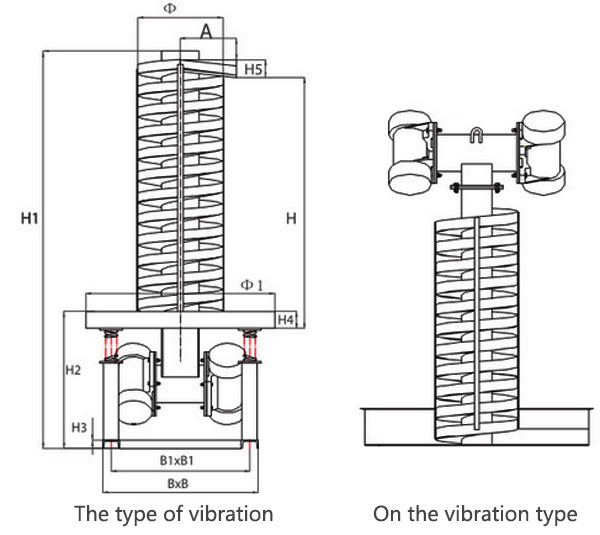

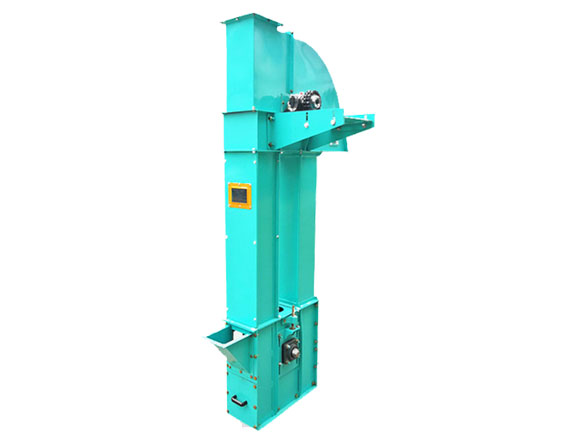

DZC series vertical vibration elevator is widely used in chemical industry, rubber, plastics, medicine, light industry, food, metallurgy, building materials, mining, grain and other industries. DZC series vertical vibration elevator is mainly used for lifting granular, powdery and massive materials. The conveyor has the advantages of simple structure, easy maintenance, quantitative delivery of materials and continuous adjustable conveying capacity. It can be used for vertical conveying of small particles in various industries. Besides lifting materials from bottom to top, it can also complete drying and cooling of materials. Separate groove and closed structure, and according to the requirements of different processes, design the screening elevator for grading of material particles and the elevator for flammable and explosive materials.

Product features :

1. Small area, simple structure, reasonable.

2. Low power consumption, no noise, easy maintenance.

3. Closed lifting effectively prevents dust and harmful gases from polluting the working environment.