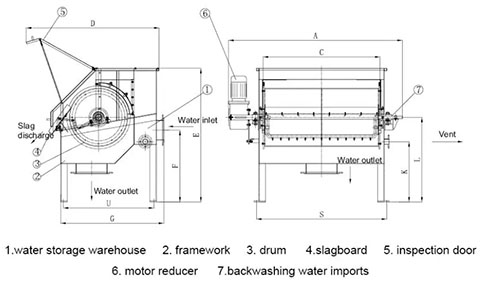

Product overview

The main structure of the rotary sieve of YTS rotary cylinder screen is the screening cylinder, which is composed of several circular sieve networks.The whole is inclined to the ground plane, and the outside is sealed by a sealed isolation cover. The cylinder rotary sieve can be provided with a comb type screening mechanism, which can be used to clean the sieve body through the relative movement of the screening mechanism and the sieve cylinder during the screening process, so as to keep the screening cylinder clean, not sticky, not sticking, not affecting the screening effect during the whole working process.

Product features

1. Rolling conveying principle is adopted, with small friction coefficient, light wear and easy clogging of sieve holes.

2. YTS series rotary cylinder sieve adopts an effective fully sealed structure, free from dust and pollution.

3.The roller support adopts the overall structure of the shaft, running smoothly, no vibration, low noise.

4.The internal drum sieve mesh accessories adopt split design, simple structure, quick and convenient replacement and maintenance.

5.Safe and reliable operation, the use of deceleration transmission, transmission efficiency, with small power, low energy consumption, energy-saving effect is obvious.

6. Different sieve mesh material can be used as required by the customer, and the size of the sieve hole can be high, the sieve efficiency is high, the service life is long, and the maintenance cost is low.

Working principle of YTS series rotary cylinder sieve: