Product overview

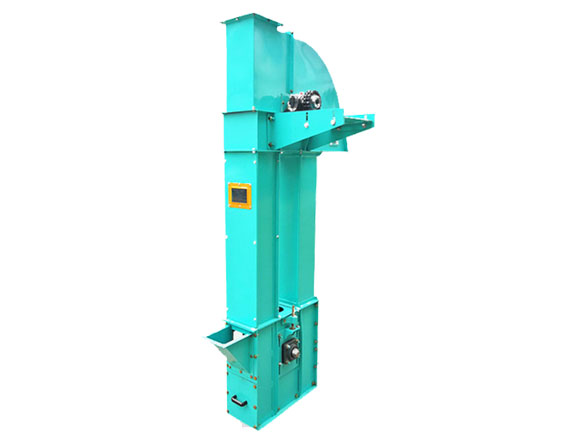

TD/D bucket elevator consists of running part (hopper and traction tape), upper part with driving drum, lower part with drum, middle housing, driving device, reverse brake device, etc. TD bucket type elevator is suitable for upward transmission of loose density less than1.5t/m3 powder, granular and small block without grinding cut and semi-grinding cut loose material, such as coal, sand, coke, cement, broken ore.

Product features

1. Low driving power. The hopper intensive layout of inflow feeding, induction unloading and large capacity is adopted, and there is almost no material return and digging phenomenon when the material is lifted, so the invalid power is low.

2. Wide range of promotion. These types of machines have less of the type and characteristics of the materials, not only to increase the normal powder, but also to increase the material, and to enhance the abrasive material, which is very polluted.

3. Reliable operation. The advanced design principle and processing method ensure the reliability of operation of the complete machine without failure time exceeding 20,000 hours. High degree of lift, the hoist running smoothly, so can reach a higher height of lift.

4. Long service life. The feeding of the elevator is of the inflow type, so that the hopper need not be used to excavate material, so that there is little pressure and collision between materials. The design ensures that the material is rarely scattered during feeding and unloading, thus reducing mechanical abrasion.