Product overview:

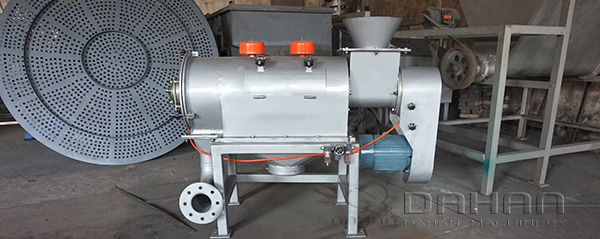

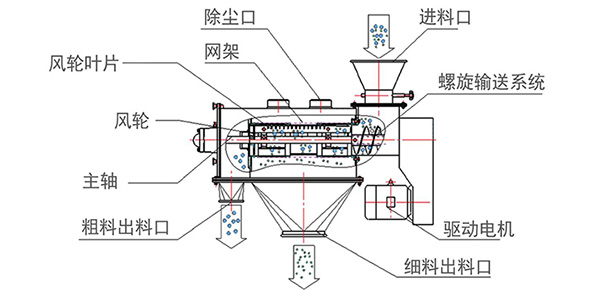

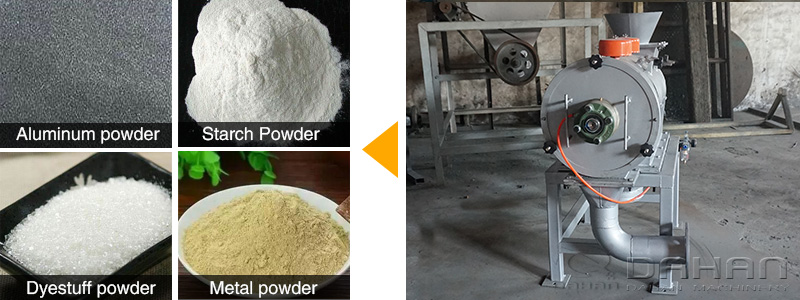

Horizontal Airflow screen is also called horizontal cyclone sieve, The models are WQS18-65, WQS30-100 and WQS50-130. Its material is stainless steel and carbon steel material. It is especially suitable for screening fine powder, low density (light gravity), slight humidity, easily adhering sticky powder or electrostatic reaction materials. Screening with fiber mesh can avoid electrostatic reaction phenomenon, and can completely solve the difficulty of production process that ordinary vibration screen can not screen.

Product features:

1. It can be used for ultra-fine powder screening to solve the difficulty of production technology which cannot be screened by ordinary vibrating screen.

2. Screen machine shell structure is novel, simple installation, easy control. The screen is scoured by cyclone and can be cleared automatically.

3. The screen machine has the function of recrushing the agglomerated material.

4. It can be used with single machine or multiple machines, running continuously for a long time, safe and reliable.

5. The new outer spherical bearing can reduce the running temperature, reduce the maintenance frequency and prolong the service life.