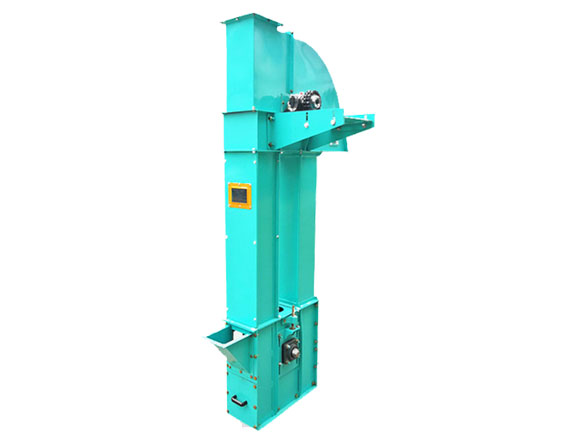

Product overview

NE series chain bucket elevator is suitable for the vertical lifting of powder materials to large blocks and other materials. It adopts the inflow feeding to replace the cutting feeding of traditional bucket elevator. It is the replacement product of traditional bucket elevator.The NE Series bucket elevator is a kind of lifting equipment of plate chain and gravity induced unloading. It applies to the vertical flow of powder, granular, small, abrasive, or non-abrasive material, like raw material, cement, coal, limestone, dry clay, and the ripe stuff.

Product features

1. Wide range of lifting. This type of hoist requires less material type, characteristics and lumpiness. Not only can improve the general powder, granular and block material, but also can improve the abrasive material. Material temperature is no more than 250 degrees.

2. Large conveying capacity. This series of lifting machines has various specifications of NE15 ~ NE 800. The lifting capacity range is 15 ~ 800m 3 /h.

3. Low driving power. These types of machines are used to feed, gravity, and the high-volume, high-volume, high-volume, high-volume, high-volume, high-volume, high-volume, high-volume. Material lifting, there is almost no material back and digging phenomenon, so ineffective power is low, the power consumption is 70% of the loop chain hoist.

4. Long service life. The feeding of the hoist adopts the inflow type. There is no need to excavate material, so that there is little pressure and collision between materials. The design of the machine ensures that material will not be spilled during feeding, lifting and unloading. Mechanical abrasion is reduced, and the conveying chain adopts plate chain high-strength and anti-wear chain, which greatly extends the service life. Under normal use, the service life of conveyor chain exceeds 5 years.