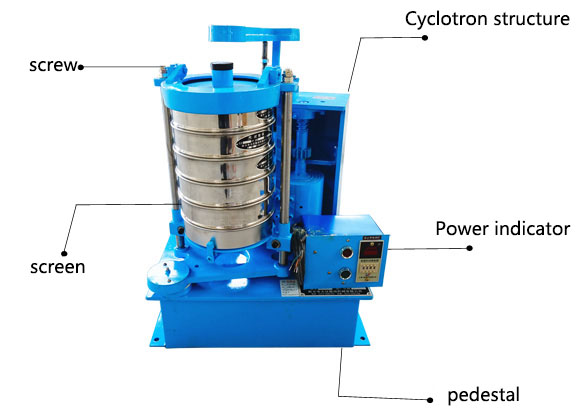

Product overview

Slap type laboratory vibrating screen is one of commonly used equipment in the laboratory,it can be pided into belt and gear slap type laboratory vibrating screen. Its structure is mainly composed of motor base,sieve set and transmission mechanism,which be equipped with special fixture,not only can assemble Φ200 standard test sieves,but can assemble sieve set of Φ 75,Φ100 and Φ300.It can be handling with convenient and flexible,and can automatically shut down.

Product features

1. Simple structure, long service life and low maintenance cost.

2. The transmission is accurate, the consistency is good, The gear drives the synchronous belt in a way that the speed ratio is precise,and no speed drop.

3.High screening efficiency and unique design makes slap screen at work and also have two forms of movement : reciprocating and clapping vibrations,

so there will be no blockage of material and the problems and fast cutting, screening thoroughly, high efficiency.

4.The timing function ensures that the inspection results are available to the screen power controller for the time of reservation, and the automatic shutdown inspection and production are consistent.