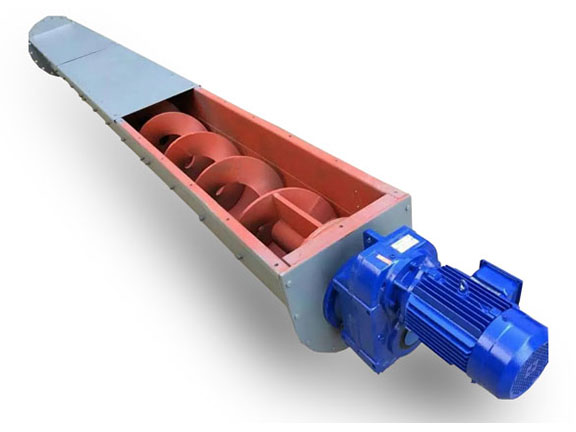

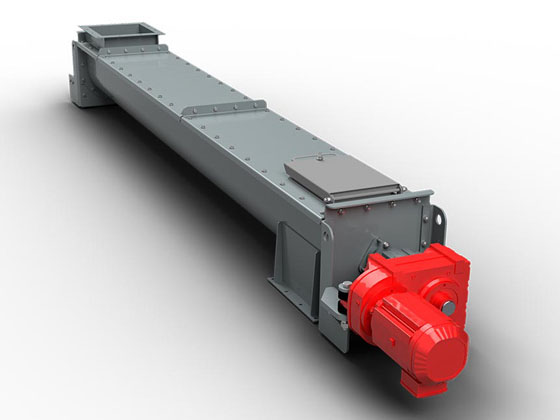

Product overview

Shaftless screw conveyor is composed of driving device, shaft less screw, u-groove, lining plate, cover plate, hopper, discharge port and so on. The products are mainly used in chemical industry, food, medicine, paper making, beverage, environmental protection and other industries to transport adhesion of strong materials, paste viscous materials (such as chemical raw materials, waste pulp, malt, sludge, etc.) and easily wound materials (such as household garbage), has a unique advantage. So the screw conveyor is also known as anti - winding conveyor, garbage disposal conveyor.

Product features

Compared with the traditional helical conveyor with shafts, because it adopts the design without a central shaft and uses the whole steel screw with certain flexibility to push materials, it has the following prominent advantages:

1. Strong anti-winding property. Without interference of central axis, it has a special advantage for conveying ribbon and easily wound materials.

2. Good environmental protection performance. The screw surface is completely closed and easy to clean, which can ensure the sanitation of environment and the materials are free from pollution and leakage.

3. Large torque distance and low energy consumption. Since the screw has no shaft, the material is not easy to be blocked, and the discharge port is not blocked, so it can operate at a low speed and drive smoothly.

4. Reduce energy consumption. Torque up to 4000N·m.

5. Large conveying capacity. The conveying capacity is 1.5 times of the same diameter of the traditional shaft screw conveyor.

6. Long conveying distance. The length of single conveyor can reach 60 meters. And according to the needs of users, multistage tandem installation, ultra-long distance conveying materials.

7. Able to work flexibly. My company's development and production of mobile shaft - less screw conveyor, mobile work, a multi-purpose machine.

8,.can not only under the discharge, but also the end of the discharge.

9. the use of special lining board, the machine can work under high temperature.