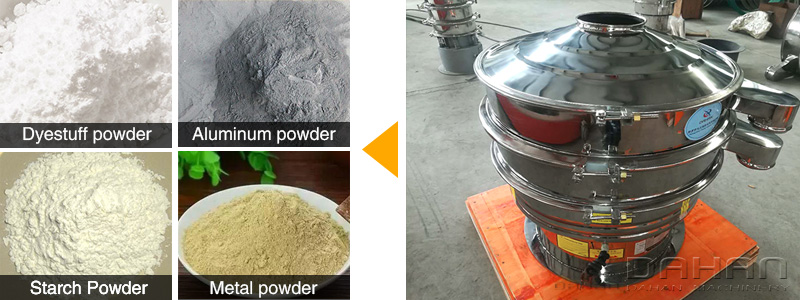

Product overview:

Stainless steel vibrating screen machine adopts stainless steel material, the diameter of the equipment is 400mm-1800mm, the screen machine inside and outside polishing, clean, no burr dead angle, the screen mesh height can reach five layers, the use of "strong" new dynamic exciter, three-dimensional power is more prominent, the scope of application is more extensive. Mainly used for food, medicine and other health requirements of the industry, equipped with seals in line with health standards, spring periphery with stainless steel skirt.

Product features:

1. The machine is made of stainless steel with no dead angle and easy to clean and disinfect.

2. It is easy to change the net, easy to operate, and the impurities and coarse materials can be automatically discharged.

3. Mesh is not blocked, powder is not flying, dust is not flying, liquid is not leaking, screen mesh is not blocked, can be screened to 500 mesh, filtering up to 5um.

4. Unique network frame design, long screen time, fast network change, only 3-5 minutes.

5. Exquisite and durable design, space saving, easy to move.

6. The screen can be up to five layers, high efficiency, any kind of fine, mucus can be screened.