Product overview

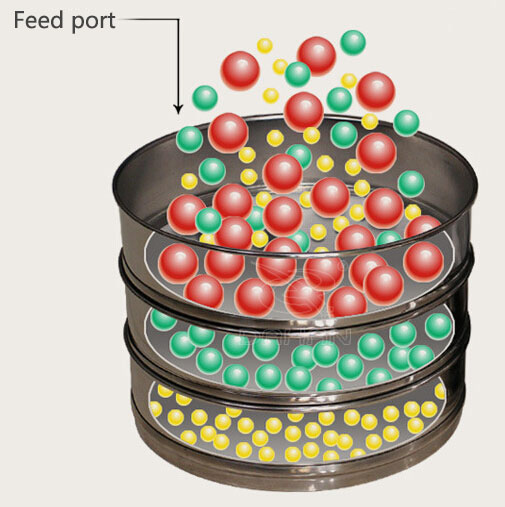

Standard soil screen is the screen that filters the soil. It is widely used in the classification, screening, analysis and testing of samples in various laboratories. Equipped with automatic laboratory shaker with higher efficiency and safety.

Product usage instruction

1.The coarse screen commonly used in civil engineering experiment is the circle hole, there has different size of bore diameters, like100,80,60,40,20,10,5,2mm, and its effective diameters is 2.0,1.0,0.5,0.25,0.10,0.075mm. The classification of screen hole in different countries and departments is also different.

2.Analytical balance. The analytical balance is pided into two types according to the range and accuracy of weighing, (1)weight 10kg, feeling1g, (2) weight 1000g,feeling0.1g.

3.Sieve machine, standard shaking screen machine in the horizontal direction shaking vibration, beating in the vertical direction. The shaking frequency is 100~200 times per minute, the bits is 50~70 times per minute.