Product overview

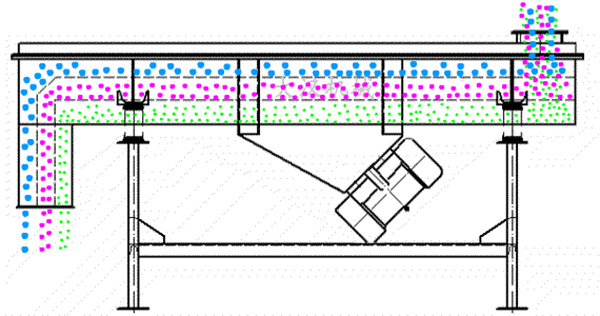

The screening process of linear vibrating screen is generally described as the material evenly enters the linear screen through the feeding port, and then screens variety of specifications on the screen, under the screen through different type of screen mesh, and finally discharge through the outlet to achieve the purpose of screening. Linear vibrating screen with high output, low energy consumption, simple structure, easy maintenance, closed structure, no dust overflow, automatic discharge and other characteristics, more suitable for pipeline operations.

Product features

1. Mature technology, reliable quality, high screening accuracy and large processing capacity.

2. The design of the screening machine is exquisite, simple in construction, easy to install, low in energy consumption and low in noise.

3. The unique design of the mesh makes the service life of the mesh longer, and it is more convenient and fast to change the mesh. It is suitable for nylon, special dragon, PP mesh and other materials.

4. the overall sealing of linear vibrating screen machine is good, no dust overflow.

5. Easy maintenance during maintenance, suitable for automation of assembly line.