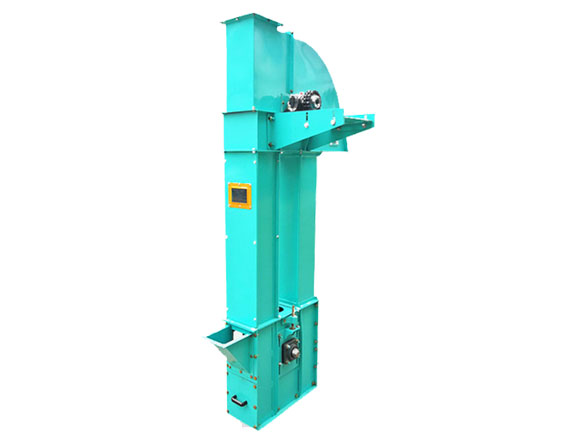

Product overview:

It is suitable for vertical conveying powder, granule and small block materials with large abrasion, such as grain, coal, cement, crushed ore, etc. The transportation height is up to 40m. It has simple structure, stable operation, extractive loading, mixed or gravity unloading.. Combination sprocket is used for wheel flange, which is easy to replace, and sprocket flange has long service life after special treatment. If gravity automatic tensioning device is used for lower part, it can maintain constant tension, avoid slipping or chain-breaking. At the same time, when the hopper is blocked, it has certain tolerance performance, which can effectively protect moving parts. Material temperature does not exceed 250 ℃.

Product features :

1. Compared with HL type bucket elevator, TH type bucket elevator with large conveying capacity and the same bucket width has nearly doubled the conveying capacity.

2. Assembled sprocket wheel is adopted, and the wheel body and rim are connected by high-strength bolts. When the sprocket wheel is worn to a certain extent, the bolt can be unscrewed, the flange can be removed and replaced, which is convenient to replace, and the material can be removed and the maintenance cost can be reduced.

3. The lower part of the fuselage adopts heavy hammer lever tensioning device, which can realize automatic tensioning. No adjustment is needed after the first installation, and the constant tension force can be maintained, so as to ensure the normal operation of the machine, avoid slipping or chain trip.

4. The traction part is a low alloy high strength ring chain. After proper heat treatment, it has high tensile strength, wear resistance and long service life. This hoist is a mixing or gravity way to unload and extract material. It is suitable for conveying powdery, granular and small pieces of low polishing material with bulk density not more than 1.5 tons/m3. The temperature of the material should not exceed 250 degrees.