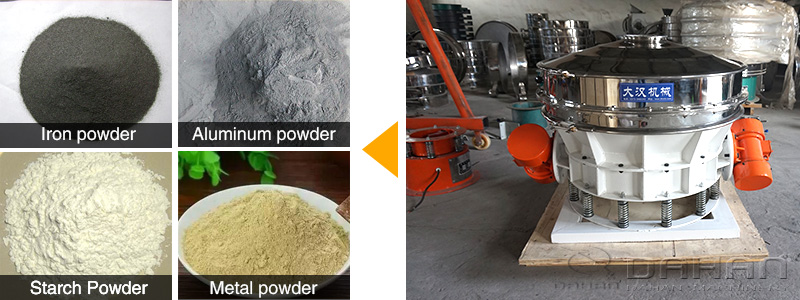

Product overview

Direct discharge sifter also known as direct discharge type vibrating screen. Vibration source is pided into single motor and double motor two structure forms, suitable for fast, large output of fine granular material classification and removal of impurity, its biggest advantage: the material in the screen machine for a short time,rapid discharge,screening output is large.It is used in flour,starch,washing powder,metal powder,additives,chemical,non-mining and other industries,in order to coarse and precise screening of granular powder.It has a lot of handling capacity and easy to integrate with production line.You can choose between 600MM and1800MM.

Product features

1. Large output.

The design of large output inlet and outlet is in the same vertical direction, and the finished products under the screen can pass through the net quickly, so as to reduce the retention time of materials on the screen surface and greatly increase the screening output. Can be used in single or multiple layers,and multistage screening can be carried out at one time。

2. Small occupied space.

Motor is designed on the outside of the equipment to reduce the height of the equipment and make effective use of the space.The equipment is easy to operate and combine with the production line.

3. Clean and hygienic.

Good sealing, No leakage of liquid and no flying dust. Internal and external easy to clean and no hygiene corner,compliance with food grade GMP specification.